- details

- parameter

- manual

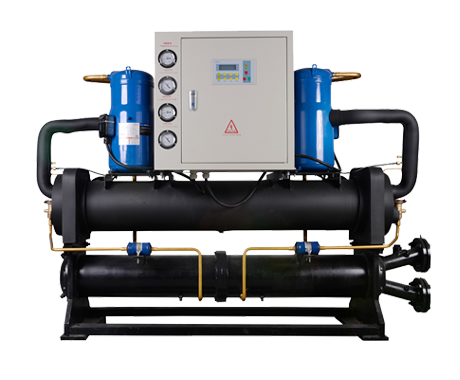

Industrial chiller water cooled chiller HX(T)-20W, with scroll type compressor, it's a normal temperature chiller, cooling capacity is 65.6KW, chilled water inlet/outlet temperature 7ºC/12ºC, cooling water inlet/outlet temperature 30ºC/35ºC.

Product description

Huaxiang water-cooled chiller is manufactured with modern and advanced technology, with high quality and beautiful appearance. The water-cooled scroll chiller uses a shell-and-tube evaporator to exchange heat between the water and the refrigerant. The refrigerant system absorbs the heat load in the water, so that the water is cooled to produce cold water, and then the heat is brought to the shell-and-tube condenser by the action of the compressor. The heat exchanger between the refrigerant and the water causes the water to absorb heat and then dissipates the heat through the water pipe to the outside cooling tower.

Water cooled industrial chiller, with High energy saving, saving 20% --30% compared with normal air-cooled chiller.

Product features:

1. The whole series adopts scroll compressor with high efficiency and low noise.

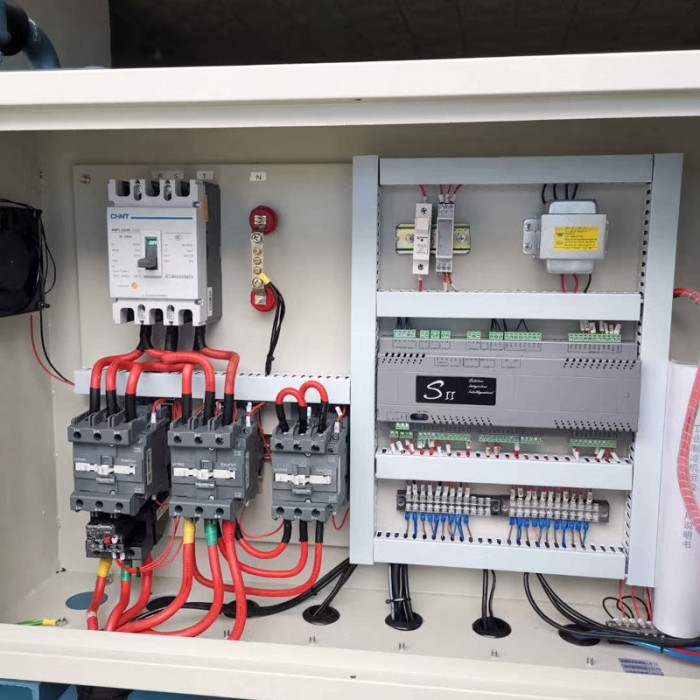

2. The controller adopts the advanced integrated single chip microcomputer, which greatly improves the anti-interference ability of the system, has beautiful appearance and is easy to install. The front and rear plates exchange data through 485 communication mode, and the whole system can be installed integrally or separately.

3. With the advanced parallel multi-loop system, each compressor can be opened and balanced according to the change of system load. When the partial load, the energy saving effect is particularly obvious.

4. The evaporator and condenser have the manufacture certificate and design certificate of class D1 and D2 pressure vessels. The condenser adopts shell and tube type to reduce the phenomenon of water pipe blockage for facilitate cleaning and maintenance.

5. The unit can be started in stages to reduce the impact on the power grid. Also, it can reduce energy consumption with multi – level automatic unloading.

6. Slim shape, easy operation, easy installation, easy cleaning and maintenance.

7. The unit is installed indoor/outdoor without special machine room and has longer service life.

Application

Industrial chillers are widely used in Plastic & Rubber industry, Metal working, Mechanical & Engineering, Chemical & Pharmaceutical, Food & Beverage, Laser, Electronics industry, Textile, Electroplating, Printing, Packaging, Ultrasound, Semi-conductor testing, Water jet, Vacuum coating, Construction and Military etc. It can accurately control the temperature to reach the cooling effect you request, increase the product quality and improve the production efficiency.

Water-cooled scroll chiller technical parameter sheet:

| Model | HX(T)-20W | HX(T)-25W | HX(T)-30W | HX(T)-40W | HX(T)-50W | HX(T)-60W | ||

| Cooling capacity | KW | 65.6 | 75 | 104 | 112.5 | 163 | 206 | |

| Kcal/h | 56400 | 64500 | 89400 | 96700 | 141000 | 177000 | ||

| Input power | KW | 17.2 | 21 | 25 | 34 | 41 | 50.5 | |

| Rated current | A | 33 | 41 | 52 | 66 | 83 | 97.8 | |

| Control system | Fully automatic | |||||||

| Work environment | ℃ | -10℃~43℃ | ||||||

| Power supply | V | 3P-380V-50Hz(Non-standard voltage can be customized) | ||||||

Compressor | Type | Hermetic scroll type | ||||||

| Power (KW) | 7.5*2 | 8.8*2 | 7.5*3 | 7.5*4 | 8.8*4 | 8.8*5 | ||

| Refrigerant | Type | R22(Optional environment-friendly refrigerant:R407C/R134A/R404A) | ||||||

| Charge volume (KG) | 10 | 12.5 | 15 | 20 | 25 | 30 | ||

| Control Mode | Thermostatic expansion valve | |||||||

| Refrigeration system | 2 | 3 | 4 | 5 | ||||

| Condenser | Type | Shell and Tube Type | ||||||

| Dia. of pipe (mm) | DN-50 | DN-50 | DN-65 | DN-65 | DN-80 | DN-80 | ||

| Cooling water flow (m3/h) | 13.5 | 15.4 | 21.3 | 23.2 | 32 | 42 | ||

| Evaporator | Type | Shell and Tube Type | ||||||

| Chilled water flow (m3/h) | 11.3 | 12.9 | 17.8 | 19.3 | 28.6 | 36 | ||

| Pressure (Mpa) | 1.5Mpa | |||||||

| Dia. of pipe (mm) | DN-50 | DN-50 | DN-65 | DN-65 | DN-80 | DN-80 | ||

| Safety device | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection, safety valve, overload protection, under voltage, over voltage etc. | |||||||

| Dimention | L (mm) | 1700 | 1700 | 1900 | 1900 | 1900 | 2300 | |

| W (mm) | 650 | 650 | 650 | 650 | 800 | 900 | ||

| H (mm) | 1650 | 1650 | 1650 | 1650 | 1650 | 1680 | ||

| Weight | KG | 600 | 750 | 850 | 1000 | 1100 | 1400 | |

| Remark: The above specifications are according to the following design conditions: 1. Cooling capacity is designed according to the following conditions: Chilled water inlet temperature 12℃, chilled water outlet temperature 7℃; Cooling water inlet temperature 30℃, cooling water outlet temperature 35℃; 2. The product specifications in the above parameter list adopt water tank coil evaporator + pump; For products with refrigerating capacity of 30HP and above, shell tube evaporator + water tank + chilled water pump can be selected; 3. Both English and Chinese language interface digital series control system; Programmable PLC system with RS485 communication; 4. The design pressure of chilled water side and cooling water side of the standard model is 1.5mpa; Container pressurized equipment (special ordering machine) applicable design pressure: 1.6mpa cooling water side, 1.0mpa frozen water side; 5. The main power supply: 3 phase 380V 50Hz; Operation power: single-phase 220V 50Hz; When ordering non-standard power supply, please apply in advance. | ||||||||

• The following instructions should be read carefully before the unit is installed to avoid unnecessary damage.

• The unit should be kept as level as possible when handling and moving, never tilted more than 30 degrees, and there should be support rods on all spreaders to avoid injuring the equipment.

• The unit can be installed on the roof or outdoor patio, and the supporting surface must be strong enough; it can withstand the weight of the unit during operation.

• The unit should not be installed in dusty, dirty, corrosive gas and humidity.

• The installation of the unit should leave enough space of more than 1.5 meters in front, back, left and right for heat dissipation and easy access for maintenance personnel.

• The set in place, should be shockproof cushion placed under the set of bottom frame, adjust the level of the set before tightening the foot screws and ambrose.

• System plumbing installation, insulation, should be designed by professionals to guide, and the implementation of the corresponding provisions of the HVAC installation specifications.

• External water piping system must be installed anti-vibration soft joints, filters, check valves, drain valves, exhaust valves, shut-off valves; such as expansion tanks should be installed above the highest part of the system 1-1.5 meters; tank capacity of about the entire system of water / 10: Exhaust valves should be installed in the highest part of the system between the expansion tanks; chilled water piping system and expansion tanks should be made thermal insulation.

• Water pumps and units, water pumps and system water piping should be connected using shockproof flexible joints, while the piping and pumps should be self-supporting brackets to avoid unit stress.

• In order to prevent welding slag and other foreign objects from entering the evaporator and causing damage to the heat exchanger tube, we are required to install a water filter of more than 16 mesh at the evaporator inlet of the unit (or at the tank refill inlet). System water pipeline flushing and insulation should be carried out before connecting with the unit, it is strictly prohibited to connect the pipeline with the unit before it is flushed clean, and lightning protection should be considered according to the height of the actual installation location of the unit.

Instructions for use

Before the user starts the machine for the first time, please read the instruction manual of the product carefully and operate the machine according to the steps stipulated in the instruction manual to ensure the safety; meanwhile, it is recommended to start the machine for the first time under the guidance of the company's commissioning engineers.

The following work must be done before starting operation

• Connect all the power supply cables and external power supply control equipment according to the requirements.

• Check the water source of water tank or expansion tank, open the exhaust valve, exhaust the air in the channel; check whether the compressor and fan or water pump running direction is correct.

• The unit will be energized in order to warm up the lubricating oil (especially in cold areas, the time is not less than 12 hours)

In case of air-conditioning system, check whether the terminal equipment operates normally.

• In the case of the main circuit power failure, carry out a test run to check whether the sequence of action is normal; check whether the compressor and fan or pump group running in the right direction

• Set industrial refrigeration (or heat pump) operation mode as needed.

After the completion of the above work, you can turn on the main power and open the chiller or air-conditioning system for the host; to be the water temperature to meet the requirements of the normal unit once the debugging is completed and put into normal operation, you must keep its power supply phase sequence unchanged.

Maintenance

• The unit has been adjusted by the company's commissioning engineers, has reached the best working condition, please do not self-adjustment.

• The unit must clean the filter at the water inlet end of the pump after 24 hours of trial operation.

Frequent operation of the switch is strictly prohibited, the number of compressor start-up shall not exceed 6 times / hour. And the interval between each start-up operation should be more than 5 minutes.

• The main circuit power switch can not be disconnected during normal use.

• The whole machine should be checked once a month, the items are:

1, electrical terminals solid bolts have no loosening.

2, the set of moving parts have no noise, whether the operation is normal.

3, each motor running current is normal, insulation resistance is normal.

• The heat exchanger of the unit should be cleaned at least twice a year with special cleaning liquid or high-pressure water to maintain good heat exchange effect.

• If the heat pump unit is turned on in winter, please pay special attention to: the temperature is below 0°C to check the circulating water insulation effect regularly. And can not cut off the unit inlet power; long-term shutdown when not in use, the water side of the heat exchanger and the system piping must be drained to avoid pipe freezing.

• The unit should be operated and managed by specialized personnel, and should be shut down in time to find out the reasons and troubleshooting when abnormal conditions are found. It is strictly prohibited to run with disease.

• If you encounter any difficulties that can not be solved, please feel free to contact the company's customer service center. Warning: In order to ensure the normal use of your unit, please follow the following tips during the use of (winter, spring): 1. Frequent shutdown, the unit's main power switch and the single-pole air switch in the electronic control box must be kept closed and energized.

2. When the ambient temperature is low, the water temperature is correspondingly low and there is a danger of freezing, the unit will automatically start the anti-freezing program to prevent the occurrence of the accident, but at this time, if you turn off the water pump and the unit power supply, then the anti-freezing program fails, the water temperature will continue to fall to the point that the water system is frozen or even frozen heat exchanger pipe, etc. In order to avoid such accidents, please you must do the following two:

1, the water pump must be linked with the unit, the unit to control the start and stop of the water pump, rather than manual control.

2, the pump and unit main circuit and control loop must be kept energized, if you can not keep the energized state. It is necessary to release the water in the water system in time.

The company's products in the installation and commissioning, if the user needs, can first communicate with the company's technical staff to confirm the site service.

Our company follows the principle of continuous product improvement, it may be difficult to notify you of some improvements and changes in product specifications, performance and materials, please understand.