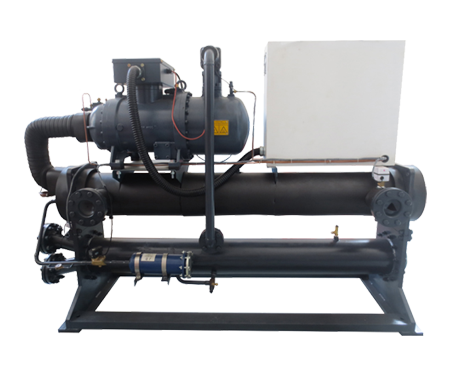

All hot and all cold units

All hot and all cold units

The air handling unit, also known as the cold air unit, is a comprehensive system for special air treatment, also known as air exchange equipment. It is a cooling device that circulates cold air to cool products, such as extrusion, injection molding, powder molding, and high-temperature unformed feed products that urgently need rapid cooling. It directly passes through cold air effective product molding, cooling packaging, and has outstanding applications in human air, environment, and other areas. Air can be processed into different temperature and humidity state points according to different application requirements. Its advantages are: strong and able to remove harmful substances to the human body such as dust, particles, bacteria, viruses, smoke, oil, etc. in the flowing air; Small wind resistance, simple and convenient equipment operation and maintenance, principles include direct injection, secondary heat exchange method, and low cost. Our company's products have passed international certifications such as CE and IS09001. Our company is at a leading level in the same industry in terms of feed, pellets, extrusion molding, and grain; Another application is air purification, where fresh air and return air are mixed in a certain proportion, and then chilled water is transported to the air treatment unit. The cold water absorbs the heat of the air, ensuring that its temperature, humidity, and air quality meet the requirements of a clean room environment before being sent into the production workshop. The air handling unit refers to the combined air handling equipment installed in the computer room, which is the core and important component of a clean air conditioning system. The composition of air handling units varies slightly depending on different production processes and regions. For example, in coastal areas with high humidity year-round, air conditioning systems only require dehumidifiers rather than humidifiers. The goal of the air handling unit is to optimize its operation as much as possible for the efficient purpose of energy conservation.